Labels for PET and RE containers

Main requirements for labels for plastic containers:

- Strength and wear resistance. The label must withstand mechanical friction during transportation and storage without losing color brightness or print clarity. For this, special glossy or matte film materials are used, resistant to moisture and abrasion.

- Optimal slip characteristics. To ensure stable and uninterrupted operation of the packaging line, labels must have the right coefficient of friction — enough to stay firmly on the bottle, but still allowing fast application at high speed.

- Aesthetics and design. A label is the brand’s visual identifier. It should be attractive, easy to read, and consistent with the product’s style. High-resolution printing allows for complex graphic elements, fine text, and vibrant colors that make the product stand out among competitors on the shelf.

- Resistance to moisture and temperature fluctuations. Beverages are often stored in refrigerators or in high-humidity environments, so the label material must be waterproof and resistant to peeling, warping, or fading when temperatures change.

Materials and technologies:

For labeling PET and PE bottles, the following film materials are used:

- BOPP (biaxially oriented polypropylene) — offers high transparency or a white glossy surface, resistant to moisture and abrasion.

- PE film — flexible and resistant to deformation, ideal for containers subject to pressure.

- Metalized films — for creating a premium appearance.

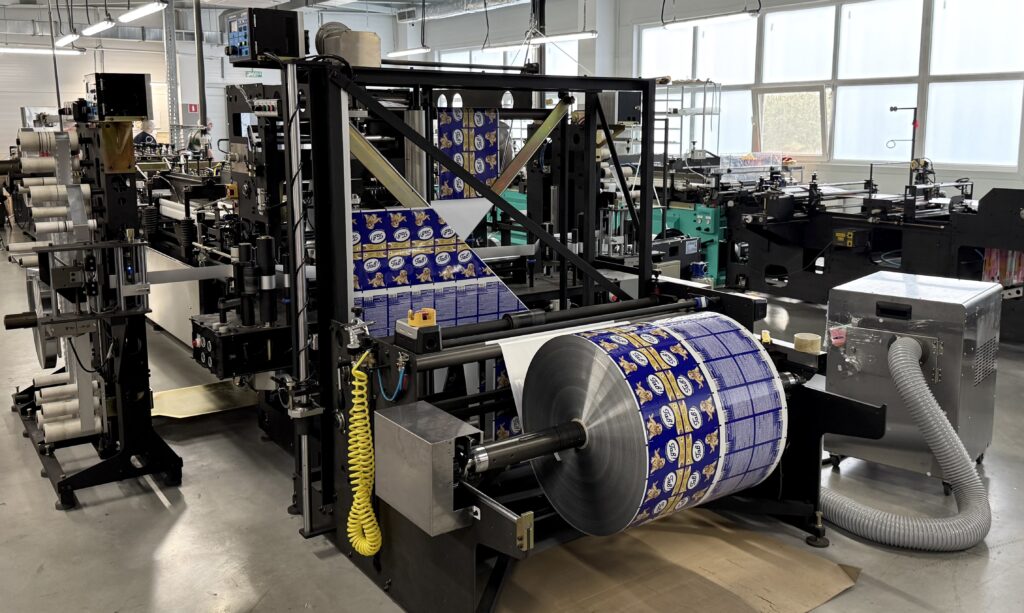

Printing on these films is done using flexographic or rotogravure printing with the option of applying spot varnish or cold glue, adding extra aesthetics and functionality to the label.

Advantages of our labels:

- Bright, abrasion-resistant printing

- Optimal film thickness and flexibility

- Compatibility with various labeling machines

- Possibility of creating custom designs