Cosmetics and pharmaceuticals

Main functions of packaging for cosmetics and pharmaceuticals

- UV protection. Films with UV-blocking properties prevent photodegradation of light-sensitive substances, preserving the stability of creams, ointments, balms, gels, syrups, and other products.

- Barrier against oxygen and moisture. Modern multilayer films (PET/PE, PET/Al/PE, BOPP, EVOH, etc.) offer high barrier performance, reducing moisture and oxygen penetration, maintaining the product’s texture and aroma, and extending its shelf life.

- Chemical inertness. Packaging does not react with its contents, which is especially important for medicinal forms and active cosmetic ingredients.

- Hermetic sealing and safety. Bags and tubes with strong welded seams prevent leakage, contamination, or the ingress of foreign particles — particularly critical for sterile products and baby cosmetics.

Types of packaging

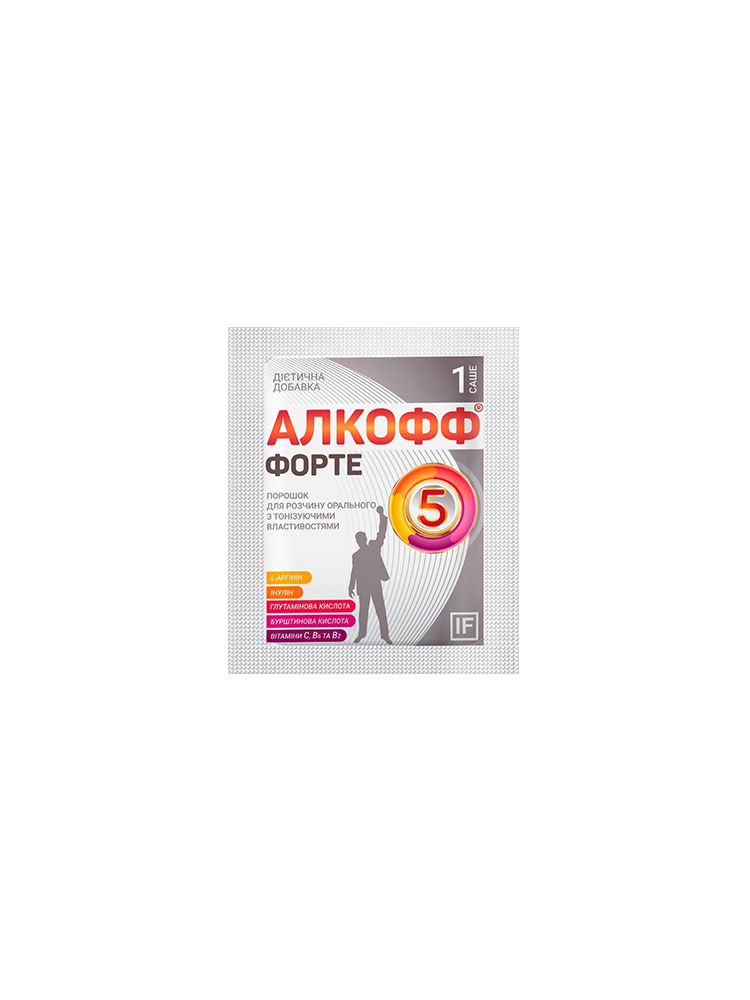

- Sachets for samples — ideal for single-use portions of creams, masks, ointments.

- Doypacks with valves or zip-locks — convenient for liquid products such as shampoos, lotions, antiseptics.

- Soft-pack packaging

- Blisters and high-barrier sachets — popular for tablets, capsules, powders.

Printing and aesthetics

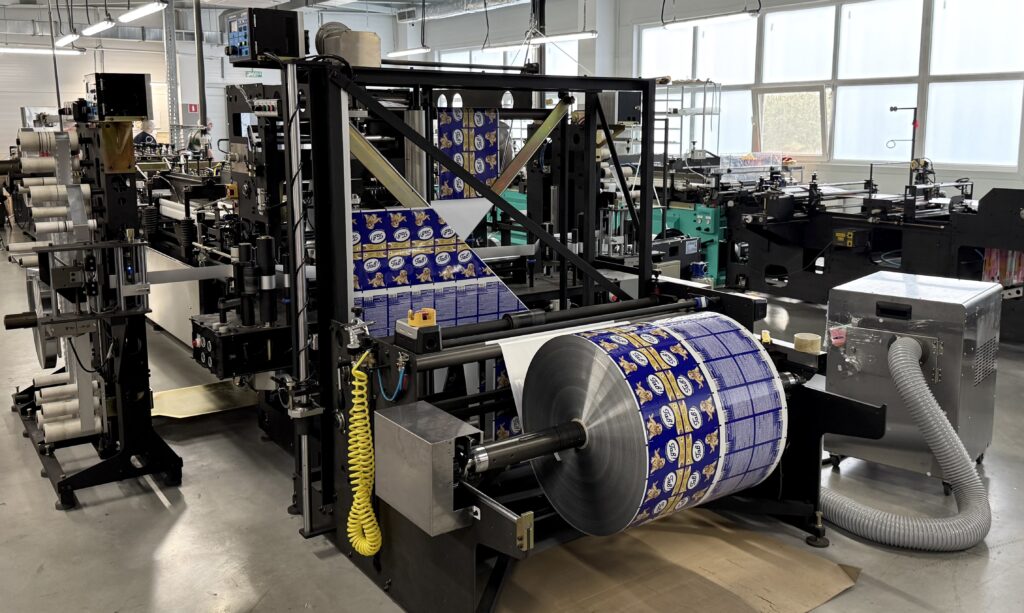

For cosmetic brands, the visual appeal of packaging is just as important as its functionality. That’s why technologies such as flexographic and rotogravure printing, embossing, spot varnishing, metallization, and matte finishes are used. This type of packaging not only protects the product but also emphasizes its premium quality and uniqueness.

Manufacturer of packaging for pharmaceuticals and cosmetics – ITAK